AT气动执行器是将气源压力经过90度变向,经一系列机械传动而转换成输出扭矩力的专用执行器。结构设计为双活塞齿条与齿轮传动,它的作用形式分为双作用与单作用(弹簧复位),作用方向可根据现场需要灵活设置成正作用或反作用。AT气动执行器区别于传统产品,集中在执行器一侧的调节螺栓更精确、更方便的调节阀门开闭位置;精密加工的内孔和外部表面进行硬质阳极氧化处理(特殊情况下阳极氧化+特氟隆涂层),耐磨性能更优越,使用寿命更经久。AT气动执行器适用于蝶阀、球阀、旋塞阀等做90°角行程的阀门控制。

产品参数

规格型号:AT330S(AT330SR)

型号意义:AT—气动执行器种类 330—气缸缸体内径 S—单作用

工作行程:90°±5°

适用气源:0.4~0.7MPa

气源接口:符合NRMAR标准

输出扭矩:1472~1981Nm(默认8根弹簧计算)

作用形式:单作用

环境温度:标准型-20℃~ +80℃

高温型-15℃~ +180℃

低温型-50℃~ +80℃

须在订货时确认!

电磁阀电源:AC220V或DC24V(也可按客户要求)

具体输出扭矩,请查看下方输出扭矩力详表。

| AT单作用输出力矩表(Nm) |

| 气源克服弹簧输出力矩(Nm) | 弹簧输出力矩 |

| 气源压力 | 0.4MPa | 0.5MPa | 0.6MPa | 0.7MPa |

| 型号 | 弹簧 数量 | 0° 开始 | 90° 结束 | 0° 开始 | 90° 结束 | 0° 开始 | 90° 结束 | 0° 开始 | 90° 结束 | 0° 开始 | 90° 结束 |

| AT52S | 8 | 7.3 | 4 | 10.8 | 7.5 | 14.3 | 11 |

|

| 9.9 | 6.6 |

| AT63S | 8 | 11.8 | 4 | 17.5 | 9.7 | 23.1 | 15.3 |

|

| 18.7 | 10.9 |

| AT75S | 8 | 23.5 | 8.7 | 34.8 | 20 | 46 | 31.2 |

|

| 36.3 | 21.5 |

| AT88S | 8 | 41.3 | 19.5 | 59 | 37.2 | 76.7 | 54.9 |

|

| 51.3 | 29.5 |

| AT100S | 8 | 76.4 | 40.4 | 102.1 | 66.1 | 127.8 | 91.8 |

|

| 62.5 | 40.0 |

| AT115S | 8 | 102.1 | 50 | 143.6 | 91.5 | 185.2 | 133.1 |

|

| 116.3 | 64.2 |

| AT125S | 8 | 137 | 74 | 190.9 | 127.9 | 244.5 | 181.5 |

|

| 140 | 77 |

| AT145S | 8 | 224.1 | 137.4 | 308.2 | 221.5 | 392.3 | 305.6 |

|

| 199 | 112.3 |

| AT160S | 8 | 269.4 | 142.5 | 379.1 | 252.2 | 488.8 | 361.9 |

|

| 296.4 | 169.5 |

| AT180S | 8 | 335.8 | 166.7 | 483.9 | 314.8 | 632.1 | 463 |

|

| 425.8 | 256.7 |

| AT200S | 8 | 492.2 | 263.8 | 698 | 469.6 | 903.7 | 675.3 |

|

| 559.1 | 330.7 |

| AT245S | 8 | 904.8 | 601.6 | 1265 | 961.8 | 1625.2 | 1322 |

|

| 839.1 | 535.9 |

| AT265S | 8 | 1339.5 | 872.8 | 1841.2 | 1374.5 | 2342.8 | 1876.1 |

|

| 1133.8 | 667.1 |

| AT330S | 8 | 2132 | 1623 | 3033 | 2524 | 3934 | 3424 | 4835 | 4325 | 1981 | 1472 |

| AT400S | 8 | 3959 | 2711 | 5627 | 4379 | 7294 | 6047 | 8962 | 7715 | 3960 | 2712

|

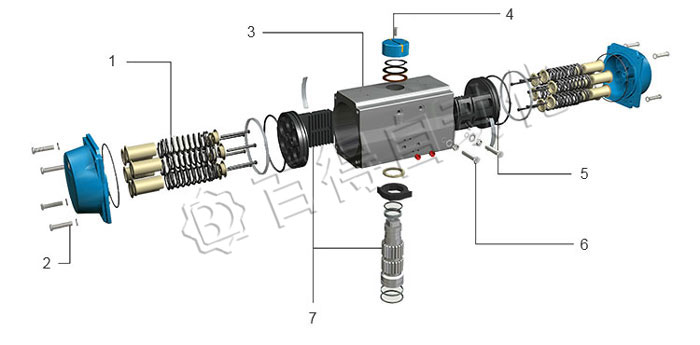

产品结构

| 1 | 组合弹簧 | 5 | 导向轴承 |

| 2 | 端盖螺栓 | 6 | 调节螺钉 |

| 3 | 铝合金缸体 | 7 | 齿轮齿条 |

| 4 | 指示器 | 8 |

|

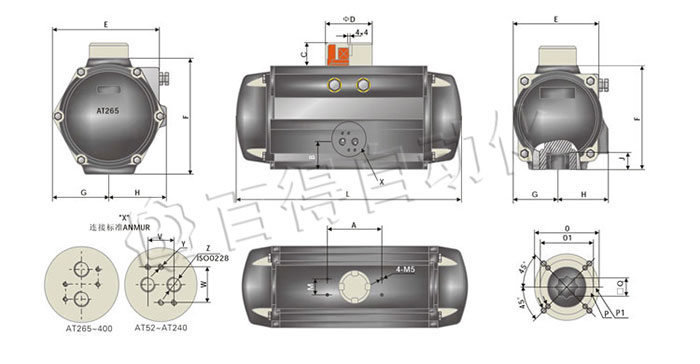

安装尺寸

| AT型气动执行器外形尺寸表 |

| 型号 | AT52S | AT63S | AT75S | AT88S | AT100S | AT115S | AT125S | AT145S | AT160S | AT180S | AT200S | AT245S | AT265S | AT330S | AT400S |

ISO

flange | F04 | F05 | F05-07 | F05-07 | F07-10 | F07-10 | F07-10 | F10-12 | F10-12 | F14 | F14 | F16 | F16 | F16 | F25 |

| L | 140.5 | 158.5 | 210.5 | 247.5 | 268.5 | 315 | 345 | 408.5 | 437.5 | 487 | 543 | 633 | 728 | 860 | 1050 |

| B | 26.5 | 30 | 30.5 | 32.5 | 38.5 | 42.5 | 45 | 47.5 | 52 | 58.5 | 62.5 | 78.5 | 165 | - | - |

| C | 20 | 20 | 20 | 20 | 20 | 30 | 30 | 30 | 30 | 50 | 50 | 50 | 50 | 50 | 50 |

| φD | 40 | 40 | 40 | 40 | 40 | 56 | 56 | 65 | 65 | 80 | 80 | 115 | 115 | 115 | 115 |

| E | 59 | 72 | 84.5 | 97.5 | 111 | 127 | 136 | 156.5 | 169 | 190.5 | 213 | 251 | 298.5 | 371 | 435 |

| F | 69 | 85 | 102 | 115 | 127 | 145 | 157 | 177 | 196 | 220.5 | 245 | 298.5 | 330 | 405 | 486 |

| G | 29 | 36 | 42.5 | 49.5 | 56 | 64 | 69.5 | 80 | 88 | 99 | 110 | 131 | 163.5 | 206 | 245 |

| H | 41.5 | 47 | 52 | 56.8 | 67 | 77 | 82 | 91.5 | 99 | 105 | 112 | 131 | 166 | 207 | 252 |

| Jmin | 12 | 16 | 16 | 19 | 19 | 24 | 24 | 29 | 29 | 38 | 38 | 38 | 48 | 55 | 55 |

| A | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 130 | 130 | 130 | 130 | 130 | 130 |

| M | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| φ01 | 42 | 50 | 50 | 50 | 70 | 70 | 70 | 102 | 102 | 140 | 140 | 165 | 165 | 165 | 245 |

| φ0 | - | - | 70 | 70 | 102 | 102 | 102 | 125 | 125 | - | - | - | - | - | - |

| P1 | 4-M6 | 4-M6 | 4-M6 | 4-M6 | 4-M8 | 4-M8 | 4-M8 | 4-M10 | 4-M10 | 4-M16 | 4-M16 | 4-M20 | 4-M20 | 4-M20 | 8-M16 |

| P | - | - | 4-M8 | 4-M8 | 4-M10 | 4-M10 | 4-M10 | 4-M12 | 4-M12 | - | - | - | - | - | - |

| □Q | 11 | 14 | 14 | 17 | 17 | 22 | 22 | 27 | 27 | 36 | 36 | 36 | 46 | 55 | 55 |

| V | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 40 | 40 | 40 | 40 |

| W | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 45 | 45 | 45 | 45 |

| Y | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M5×8 | M6×10 | M6×10 | M6×10 | M6×10 |

| Z | 1/8〃 | 1/8〃 | 1/8〃 | 1/8〃 | 1/4〃 | 1/4〃 | 1/4〃 | 1/4〃 | 1/4〃 | 1/4〃 | 1/4〃 | 3/8〃 | 1/2〃 | 1/2〃 | 1/2〃

|